During my quest for the perfect everyday carry knife (for my needs—this is obviously subjective), I came to realize there are certain benefits offered by utility knives versus traditional folding knives. With replaceable blades, there is no need to worry about damaging or dulling your knife when cutting abrasive materials. Sharpening is a non-issue, and if you encounter a security checkpoint, it's easy to simply toss out the blade and get a new one later. With that in mind, I decided to create my own utility knife from scratch.

My initial goal was simple: create a utility knife that is as small as possible. I wanted a knife that was as close to the size of a standard box cutter blade as I could manage, in order to create a tool that is portable and pocketable. Other considerations included the ability to operate the knife one-handed, and a pocket clip for easy portability. I later added a lanyard loop to the list of desired features, knowing that some people prefer to carry such knives on a keychain on in a bag.

First Prototypes

The first few prototypes for this new box cutter were based around another goal: could I create a functional utility knife out of only a single piece of metal? As it turns out, the answer is yes (and, as I have since learned, I am not the first to do so). The resulting knife, roughly 80mm/3.125" by 31mm/1.25" and just under 5mm thick, felt good in-hand and had a solid lockup. The brass material strikes a good balance of flexibility and durability, as well.

Despite the success, there were a few areas I felt could be improved upon. The open geometry made it a bit tricky to insert replacement blades, and with nothing to grip from the back side aside from the locking spring, extending the blade can be slightly cumbersome. These issues were minor—the knife was still completely usable and fairly reliable—but I knew there was room for improvement if I let go of some of the more arbitrary constraints. Thus, I dropped the single-billet goal in favor of more design flexibility.

Second Prototypes

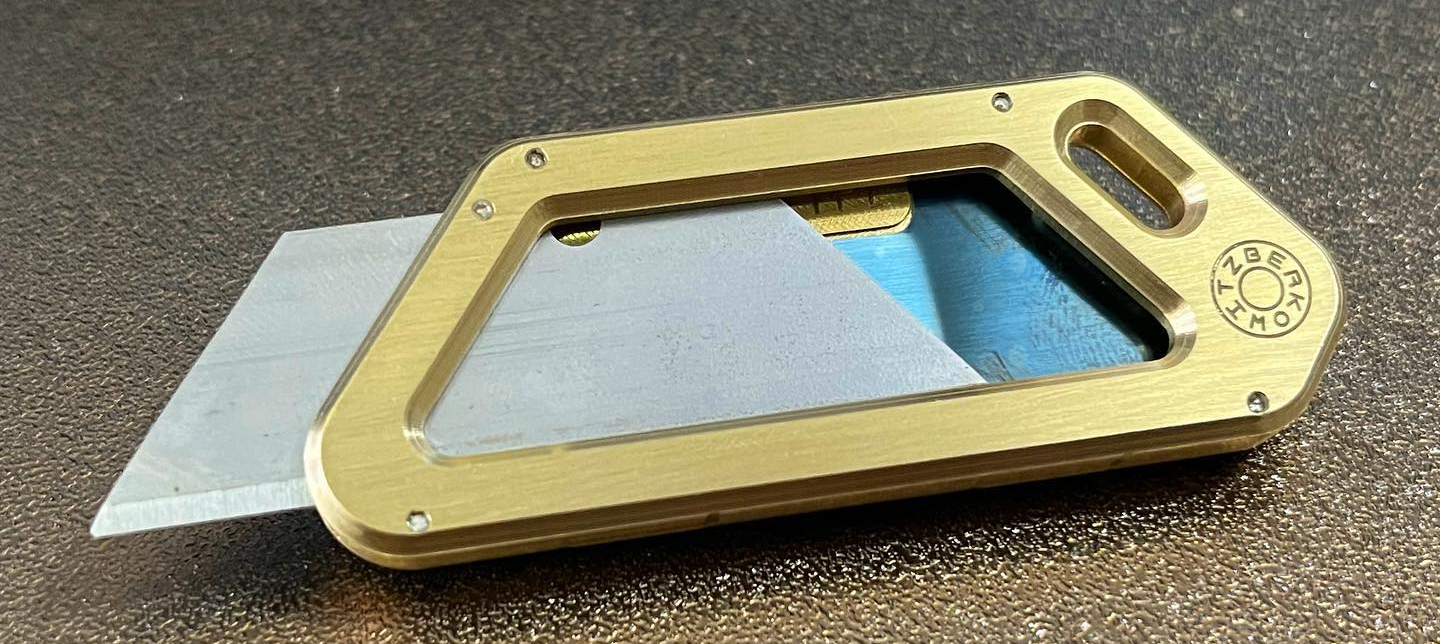

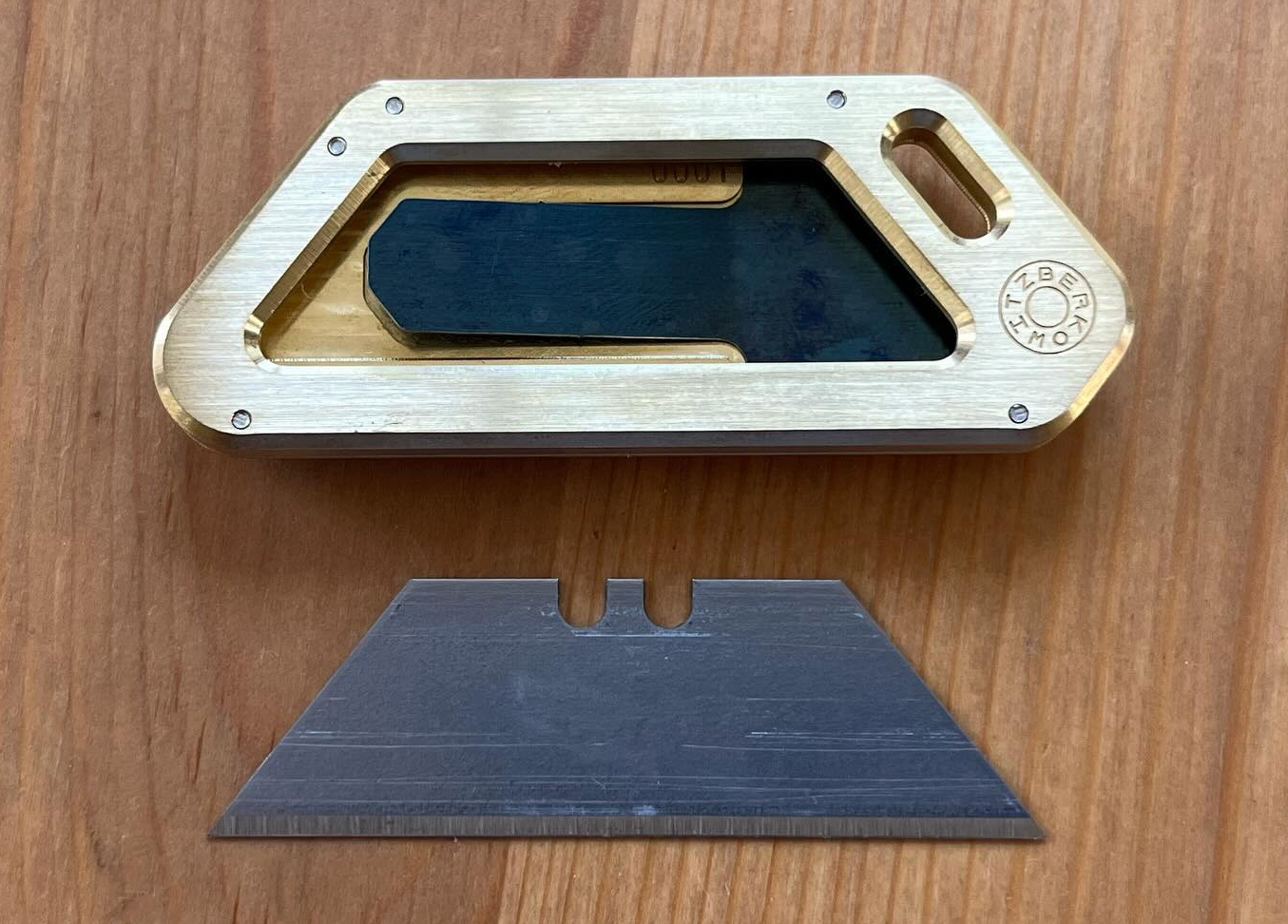

Following the success of the billet box cutter, I decided to focus on improving the overall functionality and usability of the knife. The biggest change was switching from a single-piece design to a two-piece design with a third piece for the clip. This makes machining the knife much easier and more reliable, and allows for blade retention geometry that is easier to use. Replacing blades on this version is extremely easy, and the action of extending and retracting the blade is smooth. Additionally, the detent pin used to lock the blade in position was switched from an integral piece of geometry to a steel screw, providing more resistance to wear and the ability to be replaced if needed. Moving the pocket clip to the back of the knife also makes the profile more compact and allows it to be removed if desired. After some inital 3D printed tets, this second prototype was produced in aluminum, and then later in brass. This new prototype manages to shave off a full 10mm horizontally from the original, and is only about 1mm thicker.

This brass prototype was carried and used daily for two years without any issues before I felt ready to move on to a production run. It still works great, and remains in my toolbox to this day.

During this round of refinements, I also created a fixture plate. Following the production of the first V2 prototype, I was pretty sure the overall dimensions and geometry of the knife were in a good place, so I needed a way to more easily and reliably machine the body sections and clip. Using theis fixture, I'm able to create both halves of the body, plus the clip, with just two operations. No post-processing is required aside from tapping the screw holes and cleaning up the tool marks.

The fixture plate holds 3 parts—the front and back halves and the clip—in two orientations each.

Design Iteration

Once I was happy with the dimensions and functionality of the knife, I decided to explore some alternative construction methods. I designed a version that can be cut out of flat sheets of metal, requiring only tapping and cleaunp operations before assembly. This layered version can be produced much more easily and functions identically to the milled version. However, I prefer the look and feel of the machined version.

A test I did using a transparent material for the front side of the knife. Although the 3D printed resin used here isn't really durable enough for this purpose, it does showcase the inner workings in an interesting way that I'd like to explore further. A tougher material such as Ultem would probably be perfect. You can also see a slightly different clip geometry I explored, although the clip itself is not visible in this image.

I also designed a version of the cutter that, similar to my Mercury knife, uses an inserted spring bar. The benefit of this is that it affords more variety in handle materials and produces a cleaner exterior surface on the backside of the knife. The inserted lockbar is held in place by the handle halves, meaning no tapping is required on the thin metal. The only additional operation required is a small bend to achieve the necessary spring functionality. This is ultimately the construction method I decided to move forwards with.

Release

Following the success of the prototypes, I produced a small run of 5 knives in brass, as well as a 6th for myself. With the positive reception the initial batch received, I would like to work on producing more knives in other materials.