The Rocket Coin is a fidget toy of my own invention. Its two halves roll and tilt without swiveling, creating a unique—and incredibly satisfying—tactile experience. It's designed to be a premium worry stone alternative, an everyday carry item that will last forever.

The Mechanism

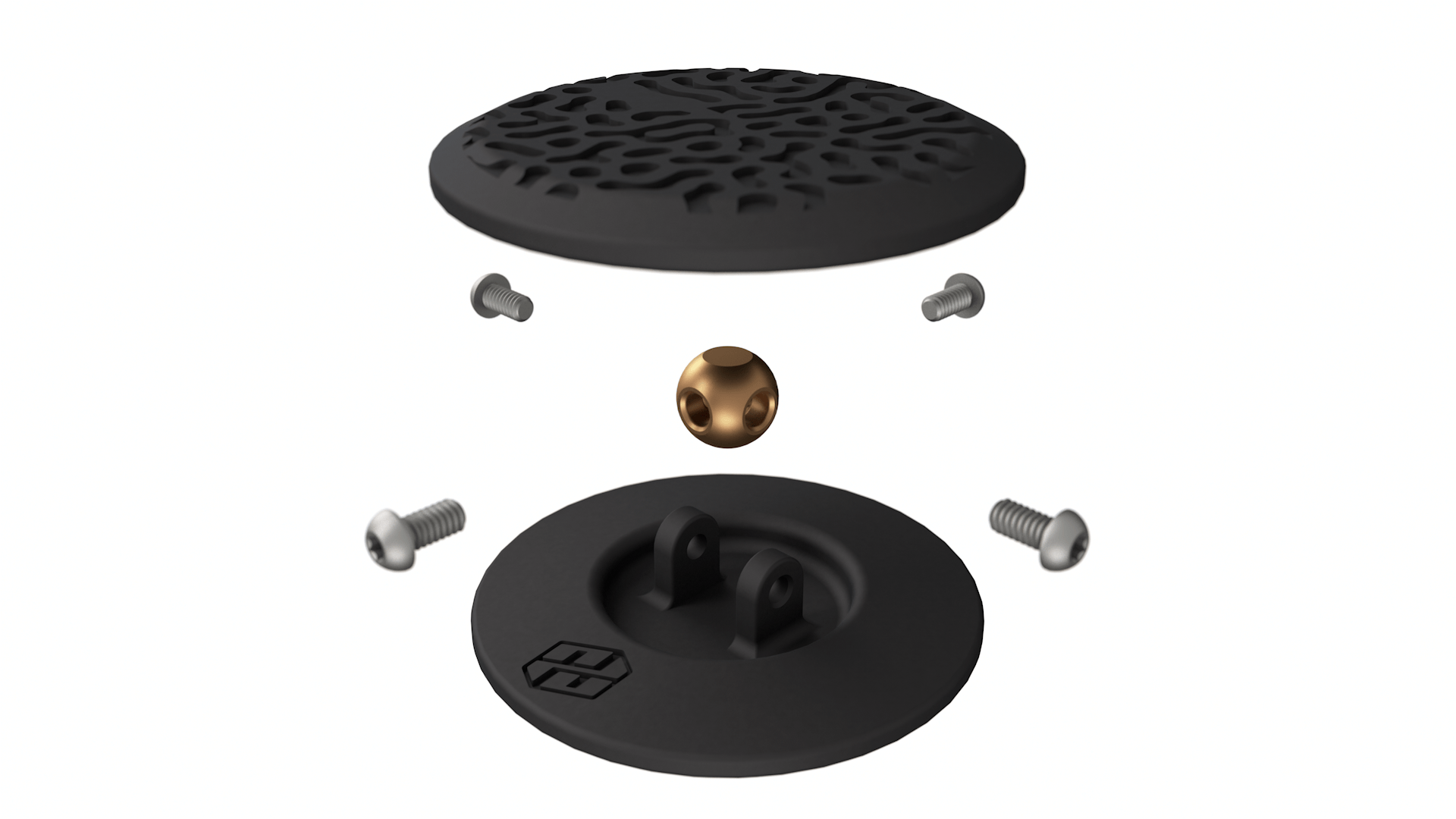

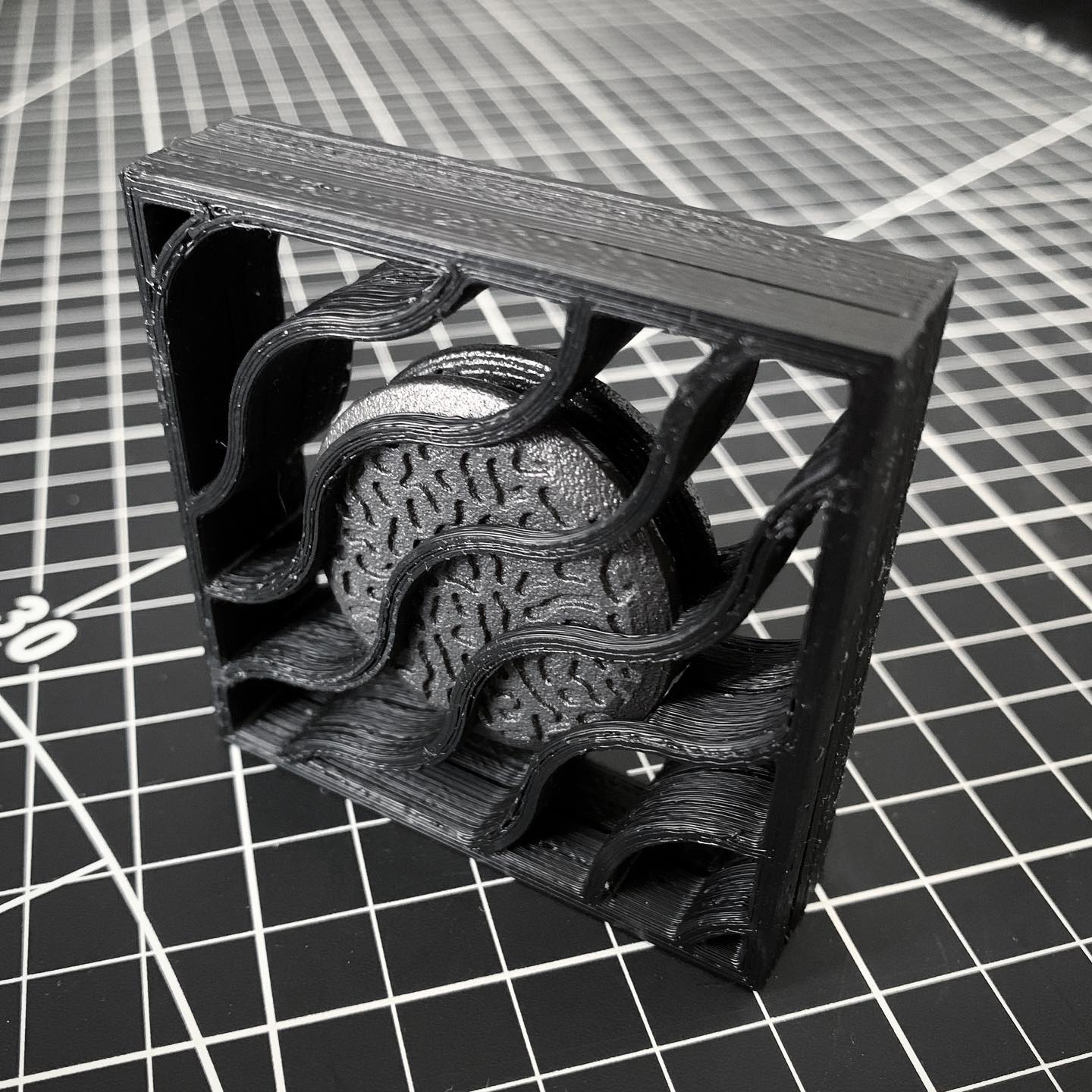

I was inspired to create the Rocket Coin by observing the motion of coins spinning on a table. The mechanism is similar to a universal joint, featuring two forks joined perpendicularly to one another with opposing hinges. The two primary halves of the coin are made of stainless steel, while the center ball is bronze. Currently, all three parts are 3D printed, with the steel halves being available in multiple colors and finishes.

The surface of both halves is imprinted with a reaction diffusion pattern, a texture created using generative processes that mimics forms found throughout nature. I like including this pattern because its organic forms contrast nicely with the otherwise rigid geometry of the object. It gives the coin a unique look and adds to the tactile nature of it.

A demonstration of the Rocket Coin, showcasing a few different ways to use it.

The Product

After several successful prototypes, I was finally able to make the Rocket Coin available for sale in my shop. Since this is a premium product, I decided it needed some premium packaging to go with it. The packaging serves two purposes:

- Protects the product during shipping

- Augments the experience of receiving and opening the package

Fortunately, since this product is not available in any brick-and-mortar stores, I didn't need to worry about spaces for branding, bar codes, etc. I designed a two-part box that clamps around the coin seamlessly, leaving it suspended in the center. The effect is surreal, almost as if the coin is floating within the package, and the coin is perfectly protected during transit.

Looking Ahead

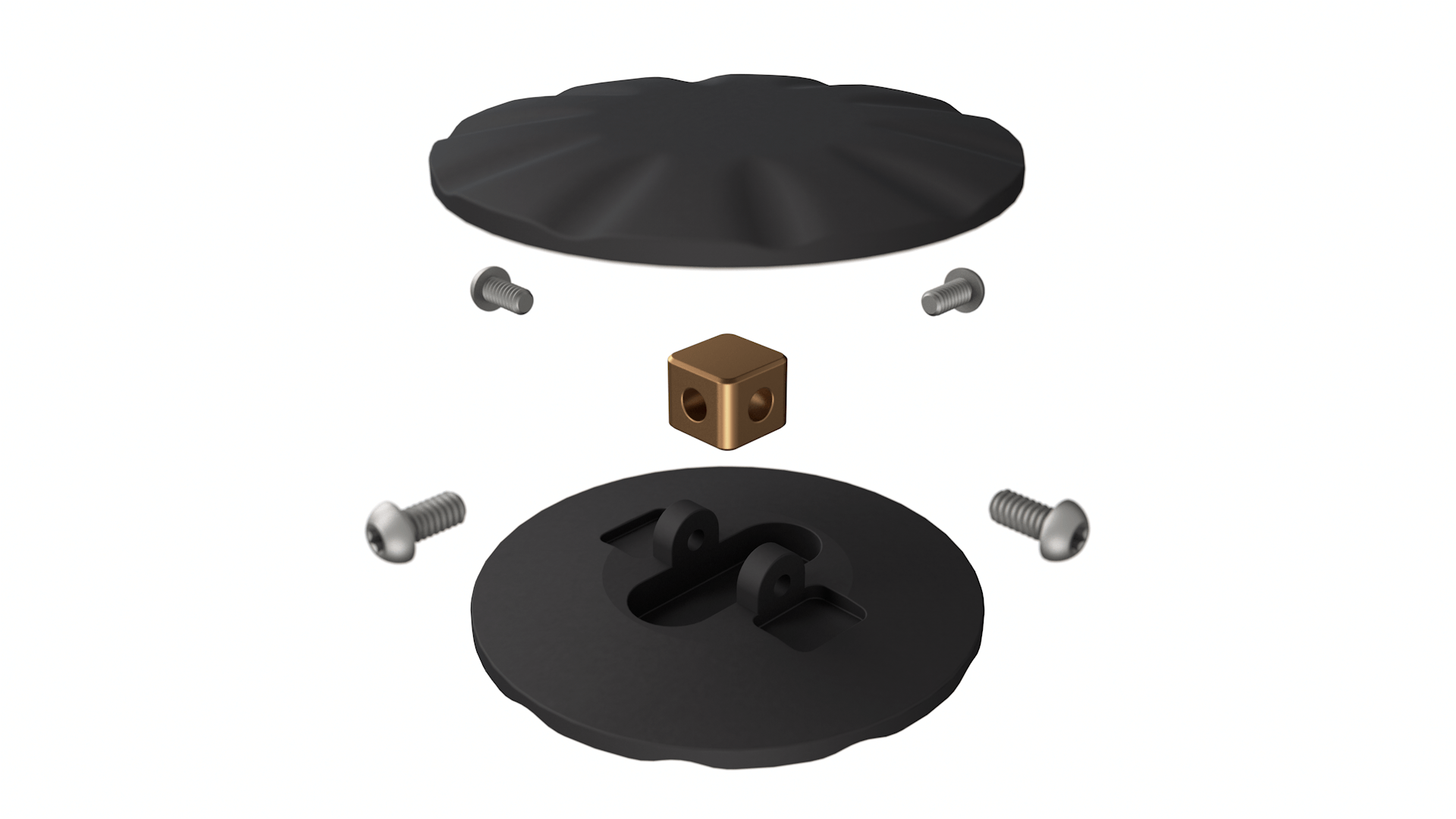

The current version of ths Rocket Coin was designed specifically with 3D printing in mind, with tolerances and geometry that are optimized for those manufacturing processes. In the future, I would like to create a CNC machined version of this toy, which would allow me to experiment with more materials and variations as well as reduce the overall cost. I've designed a new version that is optimized for milling, though as of yet I haven't had an opportunity to produce any new prototypes.

The new geometry is optimized for milling operations. I'm still exploring the top/bottom texture, so that is likely to change.